Boiler Digital Twin

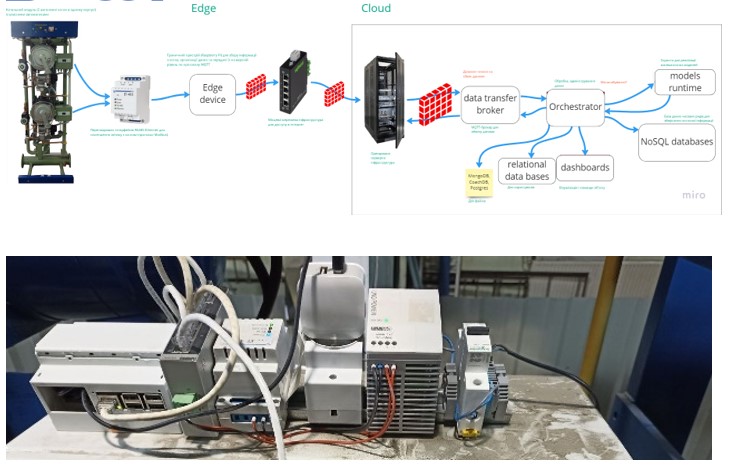

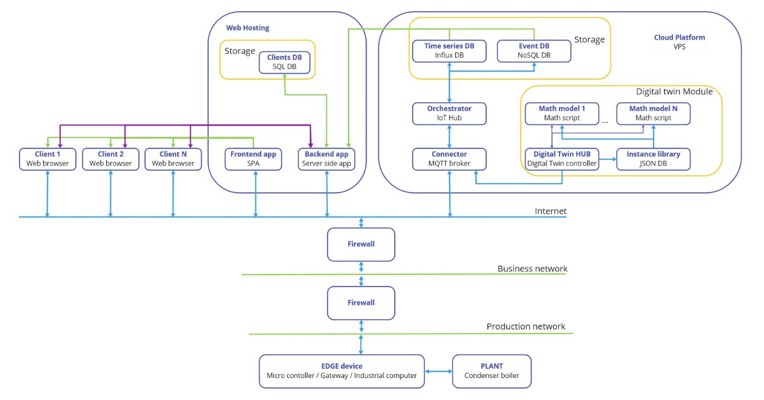

The solution have a hardware and software parts. Hardware presented by modernized control system, sensors and edge device. In other hand software presented by cloud platform, IoT Hub, Digital Twin software, Databases and Visualization system.Information

- PartnerUIT

- CityBila Tserkva

- CategoryManufacturer

- Year2022

The solution have a hardware and software parts. Hardware presented by modernized control system, sensors and edge device. In other hand software presented by cloud platform, IoT Hub, Digital Twin software, Databases and Visualization system.

At the beginning of the project SME team with support from KPI DIH elaborated Technology Application Roadmap (TAR).

In requirements specifications section the necessary hardware and software components were identified and counted. Some equipment was bought, some was rented from Centre 4.0 KPI DIH.

Mid term status report was elaborated in time. On this stage SME team have developed an edge device and configured cloud platform for gathering data.

At the second part of project period a team concentrated on developing digital twin software, increasing model accuracy and reaching business KPIs. The results described in a final report.

Implementation plan was also elaborated.

Seven KPIs were declared in TAR. Three of them are technical KPIs.

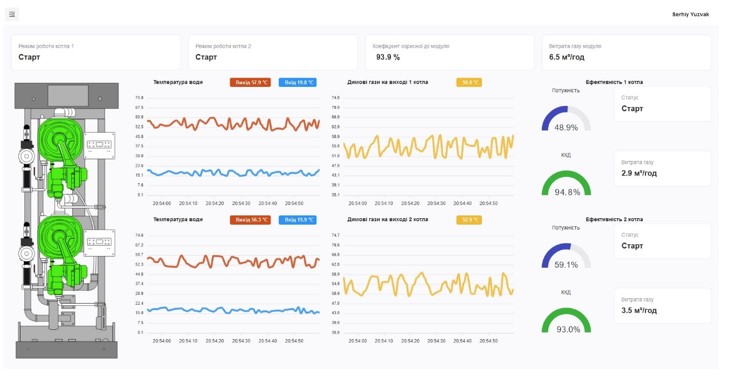

In particular conditions accuracy of heating equipment dynamic models reached 82%. When 80% was target value.

Calculated value of reducing of Fuel consumption is near 5%. About 4.4% could be saved through maintenance optimization. And up to 2% may reduced due to control system adjustment.

The third is saving time for commissioning and maintenance activities. Remote monitoring of equipment can reduce unnecessary trips for service teams. Today 2 team need to visit an site twice a month. With digital twin system high-qualified personnel can stay on manufacturing, while team of 2 members can reduce to 1 serviceman.

Intellectual property report was done with support from Centre 4.0 KPI DIH.

The project activity is described at least in two media resources. Links on the articles are shown on the slide.

SME has organized two workshops. There the concept of a Boiler Digital Twin was presented.

Urkinterm has a wide network of customers and partners in Ukraine. Agreements about testing the developed system on the partners’ areas were reached with 4 partners.

Centre 4.0 KPI DIH have provided consulting for TAR elaboration, technical consultations, training about digital twins’ essence, elaboration math equations, access to automatic control lab and temporary leased the necessary control equipment. Company Ukrinterm plans to continue cooperation with the Centre 4.0 KPI DIH to further improve the Digital Twin system.

In particular conditions accuracy of heating equipment dynamic models reached 82%. When 80% was target value.

Calculated value of reducing of Fuel consumption is near 5%. About 4.4% could be saved through maintenance optimization. And up to 2% may reduced due to control system adjustment.

Remote monitoring of equipment can reduce unnecessary trips for service teams. Today 2 team need to visit an site twice a month. With digital twin system high-qualified personnel can stay on manufacturing, while team of 2 members can reduce to 1 serviceman.